Mil-Spec Silicone Rubber Grommet | Military Specification

Part # MS35489-24X

Part # MS35489-24X

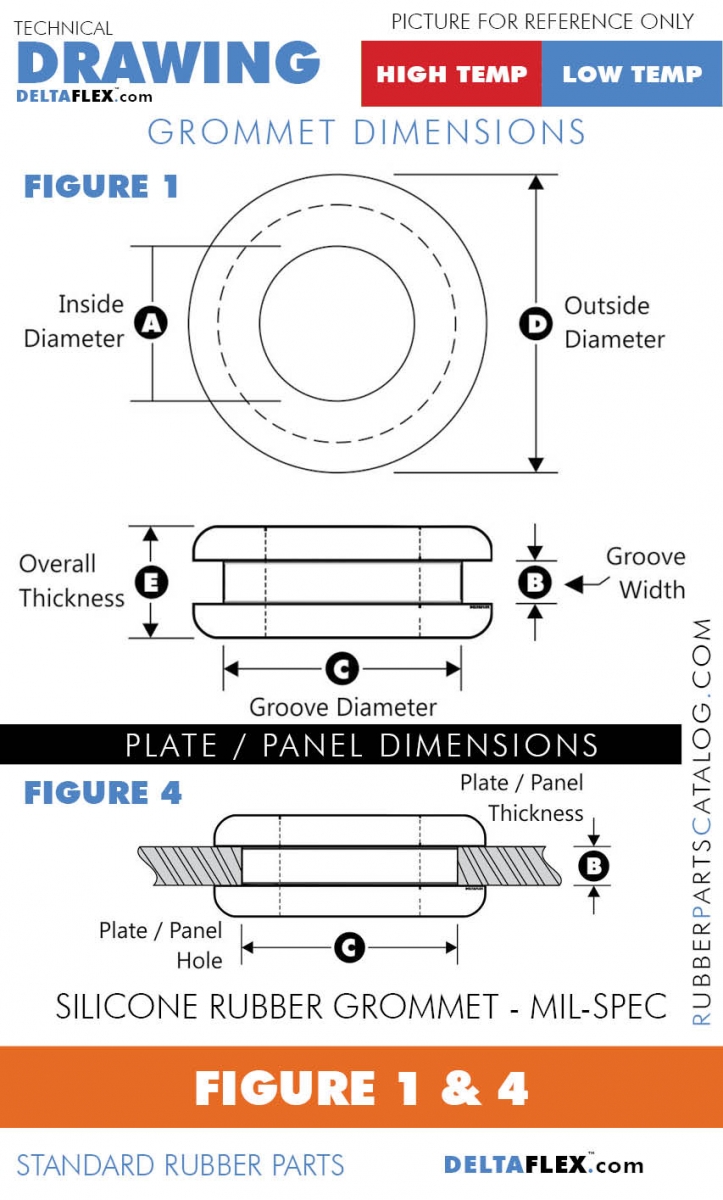

DeltaFlex supplied Mil-Spec Rubber Grommets can used in both military and industrial applications. Made from silicone rubber, these rubber grommets can be perform in HIGH Temperature as well as LOW Temperature environments.

Additional Images

| Plate / Panel Properties |

|

|

|||||||

| Part No. | MS35489-24X | ||||||||

| MS35489 Dash No. | 24 | ||||||||

| Manufacturer | DeltaFlex | ||||||||

| Part Category | Standard Rubber Parts | ||||||||

| Part Section | Rubber Grommet | ||||||||

| Part Type | Mil-Spec Rubber Grommet | ||||||||

| Application | High Temp / Low Temp | ||||||||

| Material | Silicone | ||||||||

| Durometer | 50 Duro | +/- 5 Duro | ||||||||

| Color | Red or Orange | ||||||||

| Part Status |

Call +1 800 657-0747 or use the

webform to the right on this page

|

||||||||

| Part Alternative | Call +1 800 657-0747 or use the webform to the right on this page. | ||||||||

| MS35489-24 - Oil Resistant | AN931-16-30 | ||||||||

| MS35489-24S - Split | GM-2301-NBR50BK | ||||||||

| Catalog Page No. |

|

||||||||

|

GROMMET PART NO.

|

MS35489-24X | Military Specification Rubber Grommet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shoulders / Corners

Depending on the mold that is used in the production of this rubber part the radius on the shoulder may differ from pictured. Please call 262.632.2345 or use the webform to the right or on the bottom of the page if this is critical to your application.

Tolerances

Standard industry tolerances apply. These tolerances and other technical information are available upon request or can be found on this website Click Here. Please call 262.632.2345 or use the webform to the right or on the bottom of the page.

PPAP / Material Certification

If you or your customer require a PPAP or detailed material test data sheet, a fee and/or MOQ (minimum order quantity) may be required. If you need assistance please use the webform to the right or if you require immediate assistance, please call 262.632.2345.

Custom Designs & Special Rubber Compounds

Customized designs and special elastomer compounds for specific problems are available. These may result in specifications and dimensions other than shown.

Availability

A part’s listing on this website or in our publications do not guarantee its availability. Please call 262.632.2345 or use the webform to the right or on the bottom of the page.

Custom Parts

Our custom molding department can make a part just for your application.

Engineering

Would you like some assistance in selecting the right mount for your application? Our engineering department can help. Please call or use the webform below. We will be glad to assist.

Not what you are looking for?

Our knowledgeable staff can assist you with whatever you need. From Special Packaging, Overnight shipments to applications engineering. DeltaFlex is ready to help find a solution.

Engineering Assistance

"Frequently vibration isolation problems require a system engineering analysis..." - Put us to work for you.

DeltaFlex has the computer capability, as well as specialized programs, for analyzing engine/transmission combinations. The output from these analyses is a mounting proposal which optimizes performance over the complete range of operating speeds. This service is available to you upon request. If you require this type of engineering assistance please call 800.657.0747 we will be glad to assist you.

What is the impact of Vibration Control?

The biggest impact that vibration isolation can have, is with the end users of our customers products, more importantly their perception of the quality of those products.

Values states herein represent typical values as not all test are run on each lot produced. For formalized product specifications or specific product end uses, contact Customer Service 262.632.2345.

A part’s listing on this website does not guarantee its availability.